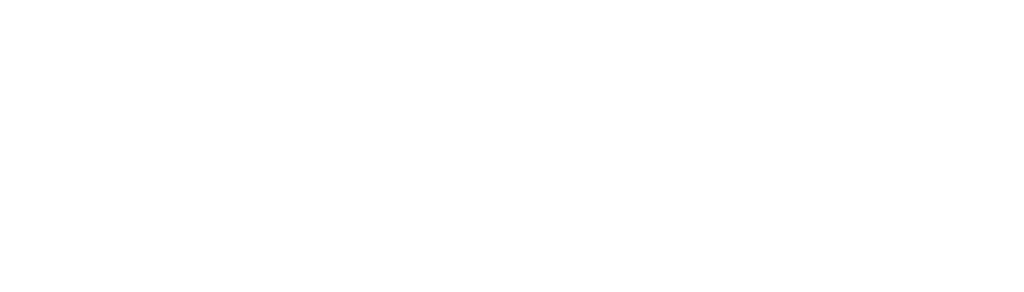

Offset printing stands as one of the most widely used commercial printing methods in the world today, representing a cornerstone technology that has revolutionized how we produce books, magazines, newspapers, brochures, and countless other printed materials. This sophisticated printing technique, which transfers ink from a printing plate to a rubber blanket and then onto the printing surface, has become the gold standard for high-volume, high-quality printing projects across virtually every industry.

The significance of offset printing extends far beyond its technical capabilities. It represents a perfect marriage of quality, efficiency, and cost-effectiveness that has made it the preferred choice for businesses, publishers, and organizations seeking professional-grade printed materials. From small local businesses producing marketing materials to large-scale book publishing services handling massive print runs, offset printing delivers consistent results that maintain brand integrity and visual appeal across thousands or even millions of copies.

Understanding offset printing is crucial for anyone involved in the printing industry, whether you’re a business owner planning a marketing campaign, a publisher preparing to launch a new title, or a designer creating materials that will eventually be mass-produced. The technology behind offset printing influences everything from design decisions and color choices to budget planning and timeline management, making it essential knowledge for achieving successful printing outcomes.

What is Offset Printing?

Offset printing, also known as offset lithography, is a sophisticated printing technique that operates on the fundamental principle of oil and water repulsion. This method involves transferring ink from a metal printing plate to a rubber blanket, which then applies the ink to the printing surface, typically paper. The term “offset” refers to this indirect transfer process, where the image is not printed directly from the plate to the paper but is offset through an intermediate rubber blanket.

The basic science behind offset printing relies on the chemical properties of different materials and their interactions with ink and water. The printing plate is treated so that image areas attract oil-based ink while non-image areas repel ink and attract water. During the printing process, both water and ink are applied to the plate simultaneously. The water adheres to the non-printing areas, preventing ink from sticking to these regions, while the ink adheres only to the image areas. This selective ink application creates sharp, clean images with excellent detail reproduction.

The rubber blanket plays a crucial role in this process, serving as an intermediary that receives the inked image from the plate and transfers it to the paper. This indirect transfer method provides several advantages over direct printing methods. The rubber blanket can conform to slight irregularities in the paper surface, ensuring even ink distribution and consistent print quality. Additionally, the offset process is gentler on the printing plates, extending their lifespan and maintaining image quality throughout long print runs.

Modern offset printing typically employs the CMYK color model, using four primary colors: Cyan, Magenta, Yellow, and Key (Black). These colors are printed in succession, with each color requiring its own printing plate and ink application. When properly registered and combined, these four colors can reproduce a vast spectrum of colors and create photographic-quality images. Some offset printing operations also incorporate spot colors or special inks for specific branding requirements or unique visual effects.

The versatility of offset printing extends to various paper types and sizes, from thin newsprint to heavy cardstock, and from small format materials to large posters and banners. This adaptability, combined with its ability to maintain consistent quality across large print runs, has made offset printing the preferred method for commercial printing applications worldwide.

The Offset Printing Process: A Step-by-Step Journey

The offset printing process begins long before ink ever touches paper, starting with prepress preparation that transforms digital designs into physical printing plates. This initial phase involves color separation, where the original artwork is divided into the individual CMYK color components. Each color requires its own printing plate, and the accuracy of this separation process directly impacts the final print quality. Professional prepress technicians use sophisticated software and calibrated monitors to ensure color accuracy and proper registration between the different color layers.

Plate making represents a critical step in the offset printing process, where the digital color separations are transferred onto metal plates, typically made from aluminum. Modern plate making utilizes computer-to-plate (CTP) technology, which directly exposes the printing plates using laser technology based on digital files. This process creates plates with extremely fine detail and excellent registration accuracy. Each plate undergoes chemical processing to create the hydrophilic (water-attracting) and hydrophobic (water-repelling) areas that are essential for the offset printing process.

Once the plates are prepared, they are mounted onto the printing press cylinders, with each color requiring its own plate cylinder. The press setup involves precise adjustments to ensure proper ink flow, water balance, and registration between colors. Skilled press operators calibrate the press settings, adjusting ink density, water levels, and impression pressure to achieve optimal print quality. This setup process requires extensive experience and technical knowledge, as even minor adjustments can significantly impact the final printed results.

The actual printing process involves multiple stations, each dedicated to applying one of the CMYK colors. As paper feeds through the press, it passes through each printing station in sequence, receiving one color at a time. The precision timing and registration of this multi-color process are crucial for producing sharp, well-defined images. Modern offset presses incorporate sophisticated monitoring systems that continuously check registration, color density, and print quality throughout the production run.

Quality control measures are integrated throughout the offset printing process, from initial color proofing to final inspection. Press operators regularly pull samples during production to verify color consistency, registration accuracy, and overall print quality. Any deviations from established standards trigger immediate adjustments to maintain consistency across the entire print run. This continuous monitoring ensures that the first sheet printed matches the quality of the last sheet, regardless of whether the run consists of hundreds or hundreds of thousands of copies.

The finishing process completes the offset printing journey, involving various post-print operations such as cutting, folding, binding, and packaging. These finishing operations are often automated and integrated with the printing process to maintain efficiency and quality. The entire process, from prepress to finished product, requires coordination between multiple specialized professionals, each contributing their expertise to achieve the final printed result.

Types of Offset Printing: Sheet-fed vs Web-fed Systems

Sheet-fed offset printing represents the most common form of offset printing for commercial applications, utilizing individual sheets of paper that are fed through the printing press one at a time. This method offers exceptional print quality and versatility, making it ideal for high-quality marketing materials, brochures, annual reports, and premium publications. Sheet-fed presses can handle a wide range of paper weights and sizes, from lightweight text papers to heavy cardstock and specialty substrates.

The sheet-fed process allows for greater control over individual sheets, enabling operators to make real-time adjustments for optimal print quality. This level of control makes sheet-fed offset particularly suitable for jobs requiring critical color matching or premium finish quality. The process typically operates at moderate speeds, allowing for careful monitoring and quality control throughout the production run. Sheet-fed presses are available in various configurations, from single-color units to sophisticated multi-color perfecting presses that can print both sides of the sheet simultaneously.

Web-fed offset printing, in contrast, utilizes continuous rolls of paper that feed through the printing press at high speeds. This method is designed for high-volume production runs, making it the preferred choice for newspapers, magazines, catalogs, and large-scale book printing companies. Web-fed presses can achieve remarkable production speeds, often printing thousands of impressions per hour while maintaining consistent quality across the entire run.

The web-fed process offers significant advantages for large-volume projects, including reduced material handling, faster production speeds, and integrated finishing operations. Many web-fed presses incorporate inline finishing capabilities, such as folding, cutting, and binding, allowing for complete production of finished products without intermediate handling steps. This integration reduces production time and costs while maintaining consistent quality throughout the manufacturing process.

Web-fed offset printing is particularly advantageous for time-sensitive publications, such as daily newspapers or weekly magazines, where rapid production and distribution are critical. The continuous paper feed eliminates the time required for individual sheet handling, allowing for uninterrupted production runs. Additionally, web-fed systems typically feature automated controls that monitor and adjust print parameters continuously, ensuring consistent quality throughout extremely long production runs.

The choice between sheet-fed and web-fed offset printing depends on various factors, including print run length, quality requirements, timeline constraints, and budget considerations. Sheet-fed systems excel in situations requiring maximum print quality, versatility in substrates, or shorter production runs. Web-fed systems are optimal for high-volume production, cost-sensitive projects, and applications where production speed is paramount. Many professional Offset Printing Services maintain both types of equipment to serve the diverse needs of their clientele effectively.

Both systems continue to evolve with technological advances, incorporating digital controls, automated quality monitoring, and enhanced efficiency features. Modern offset presses, whether sheet-fed or web-fed, represent sophisticated manufacturing systems that combine mechanical precision with digital control to deliver consistent, high-quality printed products across a wide range of applications and volumes.

Key Benefits of Offset Printing

Cost efficiency represents one of the most compelling advantages of offset printing, particularly for medium to large print runs. While the initial setup costs for offset printing can be substantial due to plate making and press preparation requirements, these costs are amortized across the entire print run, resulting in dramatically reduced per-unit costs as quantities increase. This economic advantage becomes increasingly pronounced with larger print runs, making offset printing the most cost-effective solution for projects requiring thousands or tens of thousands of copies.

The superior print quality achieved through offset printing sets it apart from most other printing methods, delivering sharp text, smooth gradients, and vibrant colors that rival photographic reproduction. The indirect printing process, combined with precise ink and water balance control, produces consistently clean images with excellent detail reproduction. This quality advantage is particularly important for marketing materials, corporate publications, and premium products where visual impact directly influences success. Professional book publishing services rely heavily on offset printing to ensure their publications meet the high-quality standards expected by readers and retailers.

Versatility in substrate compatibility makes offset printing suitable for an enormous range of materials and applications. Offset presses can accommodate various paper types, weights, and finishes, from thin newsprint to heavy cardstock, coated and uncoated papers, and specialty substrates. This flexibility allows designers and publishers to choose materials that best complement their creative vision while maintaining the technical requirements for successful printing. The ability to print on different substrates within the same production facility streamlines workflow and reduces complexity for multi-component projects.

Color accuracy and consistency represent fundamental strengths of offset printing technology. The precise control over ink application, combined with sophisticated color management systems, ensures that colors remain consistent throughout the entire print run and match established color standards. This consistency is crucial for brand identity materials, where color variations can impact brand recognition and professional appearance. The four-color CMYK process, supplemented by spot colors when necessary, provides an extensive color gamut suitable for virtually any design requirement.

Speed and efficiency advantages of offset printing become apparent in high-volume production scenarios. Once the press is properly set up and running, offset printing can produce thousands of impressions per hour while maintaining consistent quality. This production speed, combined with the ability to print multiple colors simultaneously, makes offset printing ideal for time-sensitive projects and large-scale production requirements. The efficiency extends beyond printing speed to include material utilization, energy consumption, and labor requirements per printed piece.

Durability and longevity of offset printed materials exceed that of many alternative printing methods. The ink used in offset printing penetrates slightly into the paper surface while maintaining a protective layer on top, creating prints that resist fading, smudging, and wear better than many digital alternatives. This durability is particularly important for materials that will be handled frequently, displayed for extended periods, or exposed to various environmental conditions.

Environmental considerations also favor offset printing in many applications. The process uses vegetable-based inks and generates minimal waste when properly managed. The plates used in offset printing are recyclable, and modern offset printing facilities often incorporate sophisticated waste management and recycling programs. Additionally, the efficiency of offset printing for large runs means lower energy consumption per printed piece compared to alternative methods for equivalent volumes.

Essential Equipment and Technology

Modern offset printing relies on sophisticated press technology that has evolved significantly from its mechanical origins to incorporate advanced digital controls and automation systems. Contemporary offset presses represent complex manufacturing systems that integrate mechanical precision with computer-controlled operations to deliver consistent, high-quality results. These presses range from compact single-color units suitable for specialty applications to massive multi-color perfecting presses capable of printing both sides of large sheets simultaneously at remarkable speeds.

The heart of any offset printing operation is the press itself, which consists of multiple interconnected systems working in precise coordination. The plate cylinders hold the printing plates and transfer the inked image to the blanket cylinders, which in turn transfer the image to the paper. The impression cylinders provide the pressure necessary for proper ink transfer, while sophisticated delivery systems ensure accurate paper feeding and stacking. Modern presses incorporate servo-driven systems that provide precise control over cylinder rotation, registration, and timing, enabling the exceptional quality and consistency expected from professional printing operations.

Ink delivery systems represent critical components that directly impact print quality, color consistency, and production efficiency. Contemporary offset presses feature sophisticated ink fountains and roller systems that maintain precise ink film thickness across the entire print width. These systems incorporate automatic ink density controls, color measurement devices, and closed-loop feedback systems that continuously monitor and adjust ink application to maintain consistency throughout long production runs. Advanced presses may include ink preset systems that automatically configure ink zones based on job requirements, reducing setup time and waste.

Water systems in offset printing require equally sophisticated control, as the balance between ink and water directly affects print quality, color saturation, and production efficiency. Modern dampening systems utilize temperature-controlled water supplies, automatic pH adjustment, and precise metering systems to maintain optimal water balance throughout the printing process. Some advanced systems incorporate alcohol-free dampening solutions that provide environmental benefits while maintaining print quality standards.

Digital workflow systems have revolutionized offset printing operations by streamlining the path from digital files to finished products. These systems encompass computer-to-plate (CTP) technology for direct plate imaging, digital proofing systems for color verification, and production management software that coordinates workflow from prepress through finishing. The integration of digital systems with traditional offset printing equipment enables unprecedented control over quality, timing, and efficiency while providing comprehensive job tracking and quality documentation.

Quality control equipment forms an essential component of modern offset printing operations, incorporating both automated monitoring systems and precision measurement devices. Automated inspection systems can detect and flag quality issues in real-time, while spectrophotometers and densitometers provide objective measurements of color accuracy and consistency. Advanced quality control systems can automatically adjust press parameters to maintain specifications, reducing waste and ensuring consistent results throughout production runs.

Finishing equipment complements the offset printing process by providing capabilities for cutting, folding, binding, and other post-print operations. Modern finishing systems often integrate directly with offset presses to create complete production lines that minimize handling and reduce production time. These systems range from simple cutters and folders to sophisticated perfect binding lines and automated packaging systems that can deliver finished products ready for distribution.

Applications and Industries

The publishing industry represents one of the largest consumers of offset printing services, utilizing this technology for producing books, magazines, newspapers, and educational materials. Book printing companies rely heavily on offset printing for both short-run specialty publications and large-scale commercial releases, taking advantage of the superior print quality and cost efficiency that offset printing provides. The ability to reproduce detailed illustrations, photographs, and complex layouts with exceptional fidelity makes offset printing particularly valuable for art books, textbooks, and premium publications where visual quality is paramount.

Magazine and newspaper production depends heavily on web-fed offset printing systems that can handle the high-volume, time-sensitive requirements of periodical publishing. These applications benefit from the speed and efficiency of modern offset presses, which can produce thousands of copies per hour while maintaining the color accuracy and image quality expected by readers. The flexibility of offset printing allows publishers to accommodate varying page counts, paper grades, and finishing requirements within efficient production workflows.

Commercial printing represents another major application area for offset printing, encompassing a vast range of marketing materials, corporate communications, and promotional products. Brochures, catalogs, annual reports, direct mail pieces, and packaging materials all benefit from the quality, consistency, and cost-effectiveness of offset printing. Businesses across industries rely on offset printing to produce materials that accurately represent their brand identity while meeting budget and timeline requirements.

The packaging industry extensively utilizes offset printing for creating attractive, informative, and functional packaging solutions. From food packaging and pharmaceutical labels to luxury product boxes and promotional materials, offset printing provides the color accuracy, detail reproduction, and substrate versatility required for effective packaging design. The ability to print on various materials, including paperboard, plastic films, and specialty substrates, makes offset printing adaptable to diverse packaging requirements.

Government agencies and educational institutions represent significant users of offset printing services, producing everything from textbooks and training materials to forms, reports, and public information materials. These applications often require large print runs while maintaining strict quality standards and budget constraints, making offset printing an ideal solution. The durability and professional appearance of offset printed materials also support the credibility and effectiveness of government and educational communications.

Financial services industries utilize offset printing for producing secure documents, annual reports, marketing materials, and customer communications. The precision and consistency of offset printing support the professional image required in financial communications while providing the security features necessary for sensitive documents. Banks, insurance companies, and investment firms rely on offset printing to produce materials that convey stability, professionalism, and attention to detail.

Healthcare organizations depend on offset printing for producing patient education materials, pharmaceutical packaging, medical forms, and professional communications. The accuracy and consistency of offset printing are particularly important in healthcare applications where information clarity can impact patient safety and treatment outcomes. The ability to reproduce detailed medical illustrations and maintain consistent color coding supports effective communication in healthcare settings.

Cost Factors and Pricing Structure

Understanding the cost structure of offset printing requires examining both fixed and variable expenses that contribute to the overall project cost. Setup costs represent the largest fixed expense component, encompassing plate making, press preparation, ink mixing, and quality calibration procedures. These initial costs remain relatively constant regardless of the final print quantity, which explains why offset printing becomes increasingly cost-effective as print runs increase in size. The amortization of setup costs across larger quantities dramatically reduces the per-unit cost, making offset printing highly competitive for medium to large production runs.

Plate costs constitute a significant portion of setup expenses, with each color requiring its own printing plate. A typical four-color process job requires four plates, while projects incorporating spot colors or specialty inks may require additional plates. Modern computer-to-plate (CTP) technology has reduced plate costs compared to traditional film-based processes, but plates still represent a substantial fixed cost that must be factored into project budgets. The quality and durability of plates directly impact both print quality and potential reprint capabilities, making plate selection an important cost consideration.

Material costs, including paper, ink, and consumables, represent the primary variable expenses in offset printing projects. Paper typically accounts for the largest portion of material costs, with pricing influenced by paper grade, weight, size, and quantity requirements. Premium papers command higher prices but may be necessary for specific quality or aesthetic requirements. Ink costs vary based on color requirements, coverage areas, and special ink specifications, while consumables such as blankets, rollers, and cleaning materials contribute to ongoing operational expenses.

Labor costs encompass the skilled technicians required for press operation, quality control, and finishing operations. Offset printing requires experienced operators who can manage complex equipment, troubleshoot issues, and maintain quality standards throughout production runs. The labor cost per unit decreases with larger print runs as setup time is distributed across more pieces, but skilled labor remains a significant cost component that reflects the expertise required for professional offset printing operations.

Finishing costs add to the overall project expense and vary significantly based on the complexity of post-print operations required. Simple cutting and stacking operations have minimal cost impact, while complex finishing such as perfect binding, die cutting, or specialized folding can substantially increase project costs. Many offset printing facilities offer integrated finishing services that provide cost advantages compared to outsourcing finishing operations to separate vendors.

Geographic location significantly influences offset printing costs due to variations in labor rates, material costs, regulatory requirements, and market competition. Major metropolitan areas may offer more competitive pricing due to higher competition and efficiency gains from larger markets, while rural locations might provide cost advantages in labor and facility expenses. Transportation costs for materials and finished products also impact overall project economics, particularly for large or heavy print jobs.

Quantity considerations fundamentally shape offset printing pricing, with dramatic per-unit cost reductions occurring as print runs increase. The break-even point where offset printing becomes more cost-effective than digital alternatives varies by project specifications but typically occurs somewhere between 500 and 2,000 copies, depending on complexity, quality requirements, and finishing needs. Beyond this threshold, offset printing generally provides superior value for larger quantities.

Offset Printing vs Digital Printing

The comparison between offset and digital printing represents a fundamental decision point for many printing projects, with each technology offering distinct advantages depending on project requirements, budget constraints, and timeline considerations. Offset printing excels in high-volume applications where consistent quality, color accuracy, and cost efficiency are paramount, while digital printing provides advantages for short runs, variable data applications, and quick turnaround requirements.

Quality differences between offset and digital printing have narrowed significantly as both technologies have advanced, but offset printing still maintains advantages in certain areas. Offset printing produces superior image sharpness, smoother gradients, and more accurate color reproduction, particularly for photographic images and complex graphics. The ink coverage and saturation achieved through offset printing often exceed what digital systems can produce, making offset the preferred choice for premium quality applications and brand-critical materials.

Color consistency represents another area where offset printing traditionally outperforms digital alternatives. Once an offset press is properly calibrated and running, it can maintain consistent color reproduction throughout extremely long print runs, ensuring that the first piece matches the last piece precisely. Digital printing systems, while much improved, may experience slight variations in color reproduction over time and between different print sessions, making them less suitable for applications requiring absolute color consistency across large quantities.

Speed considerations favor different technologies depending on project requirements. Digital printing offers immediate production capabilities without setup time, making it ideal for rush jobs and short-run applications. However, offset printing achieves much higher production speeds once setup is complete, making it more efficient for large-volume projects. The crossover point where offset printing becomes faster than digital printing depends on job complexity and run length but typically occurs at moderate to high quantities.

Cost analysis between offset and digital printing reveals a complex relationship influenced by multiple factors. Digital printing eliminates setup costs and offers consistent per-unit pricing regardless of quantity, making it cost-effective for small runs and variable data applications. Offset printing requires significant setup investment but offers dramatically lower per-unit costs for larger quantities, creating a break-even point beyond which offset becomes increasingly economical.

Substrate versatility differs significantly between the two technologies. Offset printing can accommodate a much wider range of paper types, weights, and specialty substrates, from very thin papers to heavy cardstock and textured materials. Digital printing systems, while versatile, may have limitations on substrate thickness, texture, or coating compatibility that restrict material choices for certain applications.

Variable data capabilities represent a key advantage of digital printing, allowing for personalized content, sequential numbering, and customized information within the same print run. This capability supports direct mail campaigns, personalized marketing materials, and customized publications that would be impossible or prohibitively expensive with offset printing. However, for applications requiring identical content across all copies, this advantage becomes irrelevant.

Environmental considerations vary between the technologies, with each offering different environmental benefits and challenges. Digital printing eliminates the need for plates and reduces chemical usage, while offset printing uses vegetable-based inks and generates less waste for large runs. The environmental impact depends largely on the specific project requirements and the efficiency of the chosen printing facility.

Quality Control in Offset Printing

Quality control in offset printing encompasses a comprehensive system of checks, measurements, and adjustments that ensure consistent, high-quality output throughout the entire production process. This systematic approach begins with prepress verification and continues through final product inspection, incorporating both automated monitoring systems and skilled human oversight to maintain the exacting standards expected from professional offset printing operations.

Color management represents the foundation of offset printing quality control, utilizing sophisticated systems to ensure accurate color reproduction from original artwork through final printed products. This process begins with proper color space management and ICC profile implementation to maintain color consistency across different devices and processes. Spectrophotometers and colorimeters provide objective color measurements that verify conformance to established standards, while color management software coordinates the complex interactions between various system components.

Press monitoring systems continuously track critical printing parameters throughout production runs, providing real-time feedback on ink density, water balance, registration accuracy, and overall print quality. Modern offset presses incorporate sophisticated sensors and measurement devices that can detect deviations from established norms and either alert operators or automatically make corrective adjustments. These systems significantly reduce waste and ensure consistent quality while minimizing the need for manual intervention during production.

Registration control ensures that multiple colors align precisely to create sharp, well-defined images without color fringing or blurring. Advanced offset presses utilize servo-controlled registration systems that continuously monitor and adjust the position of each color layer throughout the printing process. Automatic registration control systems can compensate for mechanical variations, environmental changes, and material inconsistencies that might otherwise affect print quality.

Ink density monitoring maintains consistent color saturation and prevents variations that could affect brand color accuracy or image quality. Densitometers integrated into modern offset presses provide continuous monitoring of ink density across the print width, automatically adjusting ink flow to maintain established specifications. This automated control reduces the need for manual adjustments while ensuring consistent results throughout long production runs.

Quality sampling procedures establish systematic checkpoints throughout the production process where samples are pulled and evaluated against established standards. These procedures typically include initial sheet approval, periodic sampling during production, and final product verification. Sampling protocols define acceptance criteria, measurement procedures, and corrective action requirements to ensure that quality standards are maintained consistently.

Defect detection systems identify and classify various print quality issues, from obvious problems like smudging or streaking to subtle variations in color or registration. Advanced inspection systems can automatically identify defects and either alert operators or automatically remove defective sheets from the production stream. These systems significantly improve quality consistency while reducing the labor required for manual inspection.

Documentation and traceability requirements ensure that quality control measures are properly recorded and that any issues can be traced back to their source for corrective action. Modern quality control systems maintain detailed records of all measurements, adjustments, and observations throughout the production process, providing the documentation necessary for quality certification and continuous improvement efforts.

Choosing the Right Offset Printing Service

Selecting an appropriate offset printing service requires careful evaluation of multiple factors that directly impact project success, including technical capabilities, quality standards, production capacity, and service reliability. The decision-making process should consider both immediate project requirements and potential future needs to establish a beneficial long-term partnership with a printing provider that can support ongoing business objectives.

Technical capabilities assessment begins with evaluating the printing equipment and technology available at potential service providers. Modern offset printing facilities should maintain current-generation presses with advanced color management systems, automated quality controls, and appropriate finishing capabilities for your specific requirements. The size and configuration of available presses must match your typical project specifications, including sheet sizes, color capabilities, and production volumes.

Quality standards evaluation requires examining the printing service’s quality control procedures, certification status, and sample work products. Reputable Offset Printing Services maintain comprehensive quality management systems, often including ISO certification or other industry standards compliance. Requesting samples of similar work and visiting the facility can provide valuable insights into the quality standards and consistency you can expect from a potential provider.

Production capacity analysis ensures that your chosen printing service can handle your volume requirements within necessary timeframes. This evaluation should consider both current capacity and potential peak demand scenarios to avoid production delays during critical periods. Understanding the provider’s typical turnaround times, rush order capabilities, and capacity planning procedures helps establish realistic expectations for project scheduling.

Geographic location considerations impact both cost and service quality through transportation expenses, delivery times, and communication efficiency. Local providers may offer advantages in communication, oversight, and delivery times, while distant providers might provide cost advantages or specialized capabilities not available locally. The optimal choice depends on balancing these factors against your specific project requirements and priorities.

Service range evaluation determines whether a potential printing provider can handle all aspects of your projects or whether multiple vendors may be required. Full-service providers offering design support, prepress services, printing, finishing, and distribution can simplify project management and potentially reduce costs, while specialized providers might offer superior capabilities in specific areas. Understanding your typical project requirements helps identify the most appropriate service model.

Financial stability and business reputation assessment protects against potential disruptions to your printing projects. Established printing companies with strong financial positions and positive industry reputations are more likely to provide consistent service and honor commitments throughout long-term relationships. References from current clients and industry associations can provide valuable insights into a potential provider’s reliability and service quality.

Communication and project management capabilities significantly impact the success of printing projects, particularly for complex or time-sensitive work. Effective printing services maintain clear communication channels, provide regular project updates, and offer convenient access to project status information. The ability to work collaboratively on problem-solving and accommodate changing requirements contributes to successful project outcomes.

Pricing transparency and value assessment requires understanding not only the quoted prices but also the complete cost structure including any additional fees, rush charges, or change order pricing. The lowest initial quote may not represent the best value when considering quality, service, reliability, and total project costs. Comprehensive pricing discussions should address all potential cost factors to enable accurate project budgeting and vendor comparison.

Future Trends and Innovations

The offset printing industry continues evolving through technological innovations that enhance efficiency, quality, and environmental sustainability while addressing changing market demands and competitive pressures. Automation represents a major trend transforming offset printing operations, with advanced systems handling increasingly complex tasks previously requiring manual intervention. Robotic plate changing systems, automated makeready procedures, and intelligent production scheduling optimize efficiency while reducing labor requirements and potential for human error.

Digital integration within offset printing workflows streamlines operations from initial design through final delivery, creating seamless connections between digital design systems and physical printing processes. Advanced workflow management systems coordinate prepress operations, production scheduling, quality control, and finishing operations through integrated digital platforms that provide real-time visibility and control over all aspects of printing projects.

Artificial intelligence and machine learning technologies are beginning to impact offset printing through predictive maintenance systems, automated quality control, and optimized production planning. These systems analyze historical performance data to predict potential equipment issues before they occur, automatically adjust printing parameters to maintain optimal quality, and optimize production schedules to maximize efficiency and minimize waste.

Environmental sustainability initiatives continue driving innovations in offset printing technology, materials, and processes. Vegetable-based inks, alcohol-free dampening systems, and energy-efficient press designs reduce environmental impact while maintaining or improving print quality. Waste reduction technologies, including advanced recycling systems and precision material handling, minimize environmental impact while improving cost efficiency.

Hybrid printing systems that combine offset and digital technologies within single production lines offer new possibilities for customization, efficiency, and cost-effectiveness. These systems can handle variable data applications while maintaining the quality and efficiency advantages of offset printing for consistent content, providing solutions that bridge the gap between traditional offset and digital printing capabilities.

Advanced substrate development expands the range of materials compatible with offset printing, including synthetic substrates, specialty papers, and environmentally sustainable alternatives. These material innovations enable new applications and creative possibilities while supporting sustainability goals and performance requirements that traditional materials cannot meet.

Quality control innovations continue improving consistency and reducing waste through more sophisticated monitoring systems, predictive quality algorithms, and automated correction capabilities. Advanced color management systems, inline quality inspection, and closed-loop control systems ensure consistent quality while minimizing manual intervention and reducing production waste.

Market consolidation trends are reshaping the offset printing industry landscape, with larger operations acquiring smaller competitors to achieve economies of scale and operational efficiencies. This consolidation affects service availability, pricing structures, and technological investment patterns while creating opportunities for specialized niche providers to serve specific market segments.

The integration of book publishing services with advanced offset printing capabilities creates new opportunities for authors, publishers, and content creators to access professional-quality printing services efficiently and cost-effectively. These integrated services combine traditional publishing expertise with modern printing technology to serve evolving market demands for both traditional and self-published content.

Conclusion

Offset printing remains a cornerstone technology in the modern printing industry, offering unmatched quality, efficiency, and cost-effectiveness for medium to large-scale printing projects across diverse applications and industries. The comprehensive understanding of offset printing techniques, benefits, and cost structures provided throughout this exploration demonstrates why this technology continues to dominate commercial printing markets despite the emergence of digital alternatives.

The technical sophistication of modern offset printing systems, combined with advances in digital workflow integration, quality control systems, and environmental sustainability measures, ensures that offset printing will continue evolving to meet changing market demands while maintaining its fundamental advantages in quality and efficiency. The ability to produce consistent, high-quality results across massive print runs while accommodating diverse substrate requirements and finishing specifications makes offset printing indispensable for many applications.

The economic advantages of offset printing become increasingly compelling as project volumes increase, with the amortization of setup costs across larger quantities creating cost efficiencies that digital alternatives cannot match. This economic model supports the continued viability of offset printing for publishers, businesses, and organizations requiring substantial quantities of printed materials while maintaining strict quality and consistency standards.

Quality considerations favor offset printing for applications requiring superior image reproduction, color accuracy, and consistency across large production runs. The precision control possible with modern offset printing systems, combined with sophisticated quality management procedures, delivers results that meet the most demanding specifications for color-critical applications and premium products.

The future of offset printing appears robust, with ongoing innovations in automation, digital integration, and environmental sustainability ensuring continued relevance in an evolving printing landscape. The integration of artificial intelligence, advanced materials, and hybrid technologies positions offset printing to address emerging market requirements while building upon its traditional strengths in quality and efficiency.

For businesses, publishers, and organizations evaluating printing options, understanding the capabilities, benefits, and cost structures of offset printing provides the foundation for making informed decisions that align with project requirements, quality expectations, and budget constraints. The comprehensive overview presented here supports effective decision-making by highlighting the key factors that influence offset printing success and value.

The selection of appropriate offset printing services requires careful consideration of technical capabilities, quality standards, service reliability, and long-term partnership potential. The investment in establishing relationships with qualified offset printing providers pays dividends through consistent quality, reliable service, and cost-effective solutions for ongoing printing requirements.

Offset printing technology continues advancing through innovations that enhance efficiency, quality, and sustainability while addressing evolving market demands and competitive pressures. These ongoing developments ensure that offset printing remains a viable and valuable solution for high-quality, cost-effective printing across a wide range of applications and industries, supporting the information and communication needs of businesses, organizations, and individuals worldwide.